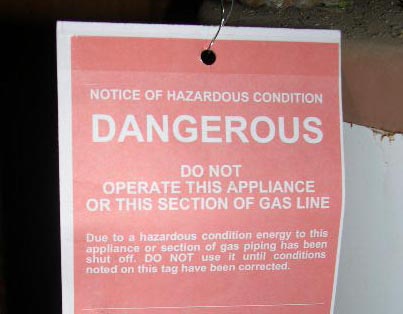

Last thing you want in an emergency situation when you call a contractor for repair is for them to shut down the furnace and inform you it is unsafe. This could be a tough uncomfortable situation for both the home owner and the service technician. It is important for to understand the reason for furnace failures and the perspective of the service technician.

Service technicians often find equipment so dangerous that they feel it is their duty and obligation to red-tag the furnace and shut it down. In the event of injury or property damage, the contractor is looked at as responsible because the customer would not have the specialized knowledge or training to make an informed consent.

How can a furnace heat exchanger fail?

- Furnace BTU over sized for the house (will cause excessive corrosion & premature failure)

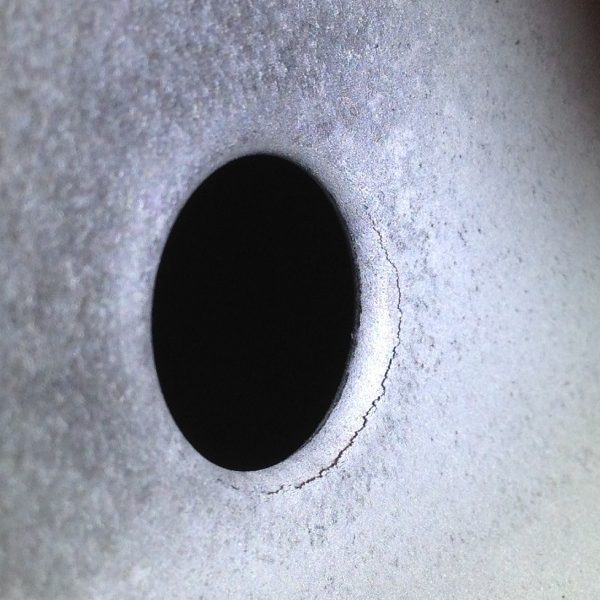

- Not enough return air going through the furnace. (causes metal stress, cracks, and opens welds or seams)

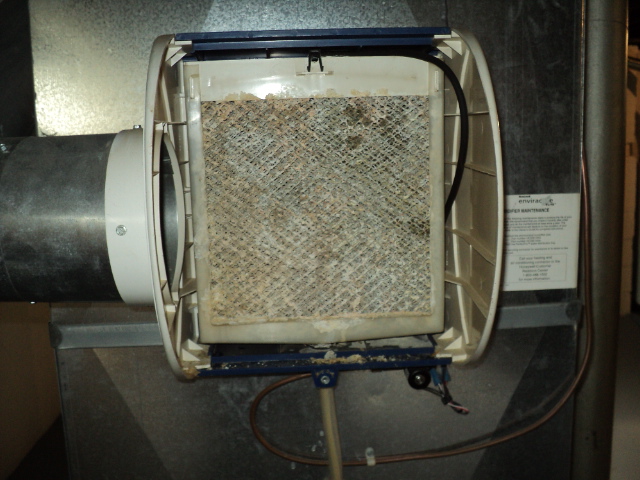

- One-inch pleated furnace filter restricting air flow across the furnace heat exchanger.

- Furnace filters not change often enough which will restrict air flow across the heat exchanger.

- The gases from house hold chemicals such as bleach, fabric softener, hair spray, ect.

- Furnaces that run during home construction or remodeling process's. (out-gassing from building materials)

- Water leaks from a humidifier that is not maintained often enough.

- Water leaks from the air conditioning coil, there are a number of possibilities that cause this.

- Manufacturing process that is not checked for accuracy often enough.

- Poor manufacturing design.

From the issues listed above you can see the majority of the failures are going to be from lack of maintenance or improper installation. Most of the causes can be identified on routine seasonal maintenance from a professional contractor. Property owners should have their heating and cooling systems maintained to maximize the lifespan of the equipment. It's important not only for safety measures, it's the law according to the International Mechanical Code:

2006 INTERNATIONAL MECHANICAL CODE® 102.3 Maintenance -

Mechanical systems, both existing and new, and parts thereof shall be maintained in proper operating condition in accordance with the original design and in a safe and sanitary condition. Devices or safeguards which are required by this code shall be maintained in compliance with the code edition under which they were installed. The owner or the owner's designated agent shall be responsible for maintenance of mechanical systems. To determine compliance with this provision, the code official shall have the authority to require a mechanical system to be reinspected.

From a technicians perspective:

IT IS A MATTER OF LIFE AND DEATH. They could be liable for damage to you or your property if allowing a faulty heating appliance to run. The main concern with faulty heating equipment is carbon monoxide. Carbon monoxide (CO) is a odorless, colorless gas that is created in the combustion process inside the unit. CO deaths and injuries occur more and more every year and in most cases could have been prevented. For more information on CO and detection methods, check our blog post.

Thanks for reading this post, for specials, maintenance tips, and contests, follow our blog!