“What is a two stage furnace, and are the benefits really worth the extra cost?”

In this post, we want to answer any of the questions you may have by providing helpful facts in a comprehensive manner.

How it work’s..

Before you can understand the savings and benefits of two stage equipment, you have to understand how it operates. Most 2 stage furnaces come with a “ECM” variable-speed blower motor. This motor has the ability to change speed under different load conditions.

The electronic components in this motor can switch power on and off in microseconds without creating an arc. The no-arc components have virtually no wear, have a long life cycle, and are more reliable.

Typical standard blower motors require a lot of energy at start-up. They use electro-mechanical devices that are subject to wear and tear every time the motor turns on or shuts off. Upon start-up, the inrush current of the motor can be 5-7 times the full load rating of the motor. Motor start-up also wears on the internal bearings because they are not fully lubricated until the motor is in motion.

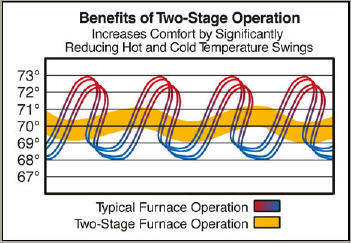

When variable-speed motor controls are used with a variable firing rate for a furnace, the temperature swing throughout the house changes like the graph above. Single stage furnace operations have 3-5 degree temperature swings and can cycle on and off up to 6 times per hour on the coldest days. The cycling on and off of a unit not only wastes energy, but wears heavily on mechanical components during the process.

Two stage furnaces run longer and cycle less creating a more consistent temperature throughout a conditioned space. On low stage heating, the gas pressure is nearly cut in half, and fan speed slows to create better heat transfer to the air. A home may be designed for 100,000 BTU furnace at 0 degrees, but only 60,000 BTU’s when its 20 degrees outside. Only on the coldest days of the year does a properly sized furnace need to run at 100%.

From the graph above, you can see the furnaces run on low stage 90% of the season. If you combine that with the energy savings from start up, wear and tear on the equipment, and more consistent temperature throughout the home, it’s worth the investment.

There are some applications where two stage operation is crucial to the safety and efficiency of a system. For instance, your home may have a “zone system” where multiple thermostats control certain sections of the house. Let’s say your upstairs bedrooms on a zone that needs only 40,000 BTU’s of heat, and the down stairs needs 60,000 BTU’s. If your single stage 100,000 BTU furnace only needs to heat the upstairs, your going to over fire the furnace and decrease the lifespan of parts and overall unit. With a two stage furnace, your operating in the specifications the system is designed for as far as heat and air flow conditions on “low stage”.

We hope this information clarifies the difference in two stage operation and helps you understand the benefits and savings over the lifetime of the equipment.

Sub-Cooled Heating and Air Conditioning provides free in-home consultations with no pressure-sales and fair & honest pricing. Give us a call today! 219-476-3776